Oh man...

Hey - Over trial and error, I don't ever use shim stock thicker than .010", and as you noted, you can and should see them sag as they get plastic, and be able to feel what the wood is doing as you bend - I do think that's critical.

E

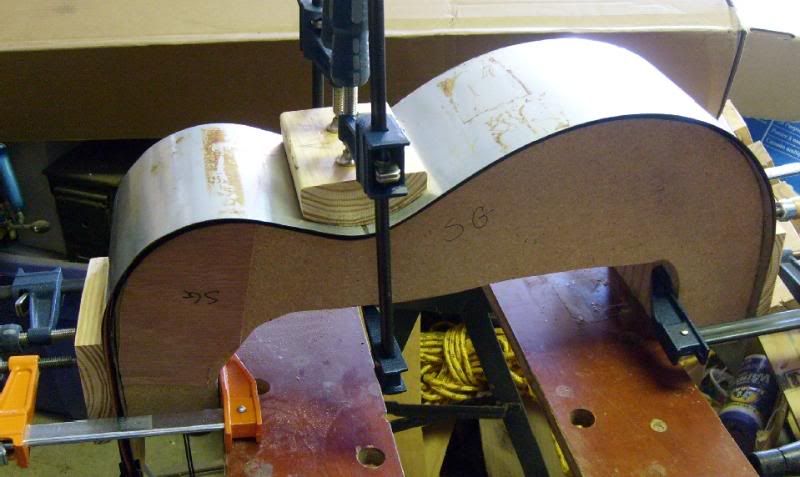

Curly Maple Cutaway for Debbie

Re: Curly Maple Cutaway for Debbie

Now for the easy side.

As I said above I waited good and long before starting the bend to make sure the heat had time to do it's thing and the wood was in the plastic stage. I bent it last night, and put it through a second cycle before going to bed. Unwrapped it after church and viola...

Very little spring back and just a tad of surface scorching...

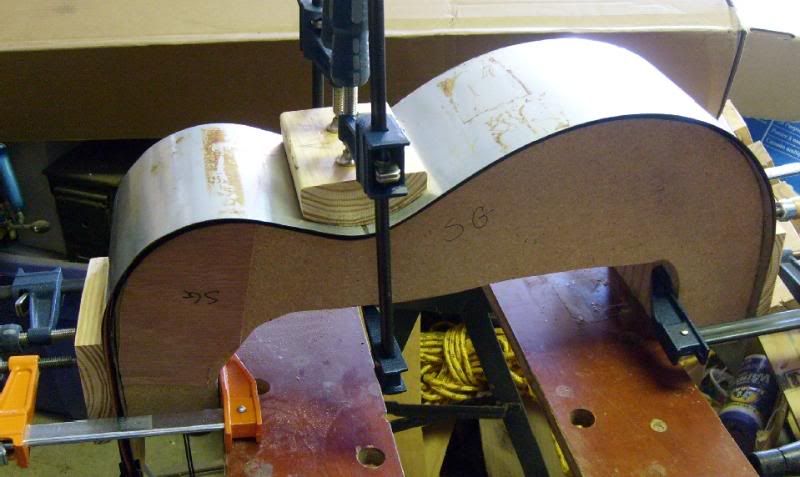

Flipped it over to check for cracks and there were none... Then I noticed something...

Then I noticed something...

See that little half triangle? That would be the dumbass symbol, or as some people call it... the mark indicating the outside front face pointing to the neck. Since it indicates the bookmatch you very rarely see it on the INSIDE!!!

Oh, did I mention that I started trimming my sides before I bend them to save on the work later? The front face is basically flat and the back has the curve in it. UNLESS YOU"RE STUPID ENOUGH TO BEND IT INSIDE OUT!!! When I was younger my dad used to say... 'Isn't it dark up there?' and I used to think 'man he must have some kinda thing about head up the ass comments...' Guess it wasn't my dad after all. It isn't the first time I've done this, but the other time wasn't a perfect bend after several less than perfect attempts, and I didn't pre-trim the side and it was purpleheart with little to no pattern to the grain anyway.

When I was younger my dad used to say... 'Isn't it dark up there?' and I used to think 'man he must have some kinda thing about head up the ass comments...' Guess it wasn't my dad after all. It isn't the first time I've done this, but the other time wasn't a perfect bend after several less than perfect attempts, and I didn't pre-trim the side and it was purpleheart with little to no pattern to the grain anyway.

Okay... once I got that off my chest, I did what several people have recommended... I did some ironing...

And rebent it the right direction this time.

More springback this time and a couple of minor cracks at the waist and lower bout. I will definitely be ordering some 0.10 shim stock.

I got out the pipe and propane torch and did some touch up...

And then got the 24 hour epoxy out (again) and patched the cracks.

Tomorrow I should be able to glue the sides to the neck and tail blocks and put the bending behind me until next time.

Raymond

As I said above I waited good and long before starting the bend to make sure the heat had time to do it's thing and the wood was in the plastic stage. I bent it last night, and put it through a second cycle before going to bed. Unwrapped it after church and viola...

Very little spring back and just a tad of surface scorching...

Flipped it over to check for cracks and there were none...

See that little half triangle? That would be the dumbass symbol, or as some people call it... the mark indicating the outside front face pointing to the neck. Since it indicates the bookmatch you very rarely see it on the INSIDE!!!

Oh, did I mention that I started trimming my sides before I bend them to save on the work later? The front face is basically flat and the back has the curve in it. UNLESS YOU"RE STUPID ENOUGH TO BEND IT INSIDE OUT!!!

Okay... once I got that off my chest, I did what several people have recommended... I did some ironing...

And rebent it the right direction this time.

More springback this time and a couple of minor cracks at the waist and lower bout. I will definitely be ordering some 0.10 shim stock.

I got out the pipe and propane torch and did some touch up...

And then got the 24 hour epoxy out (again) and patched the cracks.

Tomorrow I should be able to glue the sides to the neck and tail blocks and put the bending behind me until next time.

Raymond

I wondered why the baseball kept getting bigger. Then it hit me.

-

Josh Slaughter

- Posts: 46

- Joined: Thu Aug 28, 2008 12:49 pm

- Include Off Topic: Yes

- Location: Jamestown Tn.

Re: Curly Maple Cutaway for Debbie

Wow, you're having an awful time with those sides. I'll have to admit to getting a side bent and then noticing that I'd bent it backward. But you see, I didn't have an drawn on indicator like you had. Remember your little triangle? You shouldn't be making excuses for a stupid mistake like that.  My wood only had natural markings kinda like this

My wood only had natural markings kinda like this

I really felt like an idiot after getting those sides mixed up LOL Anyway, nice save with the iron.

Josh

PS hopefully you'll take it as goodnatured as I meant it.

I really felt like an idiot after getting those sides mixed up LOL Anyway, nice save with the iron.

Josh

PS hopefully you'll take it as goodnatured as I meant it.

-

D_H_G GUITARS

- Posts: 674

- Joined: Sat Aug 23, 2008 5:39 pm

Re: Curly Maple Cutaway for Debbie

Hi Ray, glad ya managed to get things sorted out after all.

Did you give it some thought to reducing the side a tad I almost always make sure my sides are under .085 now as my success rate is much better now.

I shoot for the target of .082 and bends like butter.

Great that things worked out for ya though.

Thxs

Hugh

Did you give it some thought to reducing the side a tad I almost always make sure my sides are under .085 now as my success rate is much better now.

I shoot for the target of .082 and bends like butter.

Great that things worked out for ya though.

Thxs

Hugh

Re: Curly Maple Cutaway for Debbie

Josh,

Nice looking guitar. What kinda wood is that anyway (besides inside out that is)

Hugh,

Yes, I plan to go thinner on the cutaway side in the future, but I hadn't had trouble with the non-cutaway side before except for burning it and/or bending it backwards.

Raymond

Nice looking guitar. What kinda wood is that anyway (besides inside out that is)

Hugh,

Yes, I plan to go thinner on the cutaway side in the future, but I hadn't had trouble with the non-cutaway side before except for burning it and/or bending it backwards.

Raymond

I wondered why the baseball kept getting bigger. Then it hit me.

- stevens

- Posts: 242

- Joined: Sat Aug 23, 2008 9:18 pm

- Include Off Topic: Yes

- Location: Bend, Oregon as of December 2012

- Contact:

Re: Curly Maple Cutaway for Debbie

Hey Ray,

Had a couple of thoughts.

The maple is pretty well quartered - inside / outside won't matter that much.

You have it corrected now though.

The bending problems you had with maple are not really uncommon with high curl wood.

Those curl grain patterns go through the side at a fairly steep angle.

Good to see you doing this one. What will the top be ?

Steve

Had a couple of thoughts.

The maple is pretty well quartered - inside / outside won't matter that much.

You have it corrected now though.

The bending problems you had with maple are not really uncommon with high curl wood.

Those curl grain patterns go through the side at a fairly steep angle.

Good to see you doing this one. What will the top be ?

Steve

Remember it's the process of building you must love.

Re: Curly Maple Cutaway for Debbie

Thanks Steve.

The problem with the inside/out side was I had already trimmed it. If I used it as is the front would not have been flat, and if I flattened it the side would have been too narrow in the back.

I couldn't remember what the top was so I looked it up. It is White Kermodie Spruce.

I'm also working the Paduak build, but it's too humid to glue and I'm ready to brace the top.

Raymond

The problem with the inside/out side was I had already trimmed it. If I used it as is the front would not have been flat, and if I flattened it the side would have been too narrow in the back.

I couldn't remember what the top was so I looked it up. It is White Kermodie Spruce.

I'm also working the Paduak build, but it's too humid to glue and I'm ready to brace the top.

Raymond

I wondered why the baseball kept getting bigger. Then it hit me.

Re: Curly Maple Cutaway for Debbie

Ray,

You are a tenacious and patient man with a resilience of spirit deserving commendation. My hat goes off to you sir for sharing this with us, I can only begin to imagine your frustration.

I think the advice so far is sound and thinning the cutaway to >.085 and also using .010 blued steel shim stock will go a long way to sorting out the problems you are now experiencing. May I just add that if you are dealing with high figured woods, an application of veneer softener such as Supersoft 2 will help avoid the heartache. What ever else, stick with it Ray my friend because every set back is a step closer to success.

You are a tenacious and patient man with a resilience of spirit deserving commendation. My hat goes off to you sir for sharing this with us, I can only begin to imagine your frustration.

I think the advice so far is sound and thinning the cutaway to >.085 and also using .010 blued steel shim stock will go a long way to sorting out the problems you are now experiencing. May I just add that if you are dealing with high figured woods, an application of veneer softener such as Supersoft 2 will help avoid the heartache. What ever else, stick with it Ray my friend because every set back is a step closer to success.

Cheers

Kim

If you always do what you've always done, you'll always get what you've always got.

Kim

If you always do what you've always done, you'll always get what you've always got.