That's looking really good, Grant. Hat is off to you guys who make your own purfling. I'll get there someday.

Pat

Size 2 Martin build coming late October

- Pat Foster

- Moderator

- Posts: 1724

- Joined: Sun Nov 30, 2008 12:19 pm

- Include Off Topic: Yes

- Location: Spokane, Eastern Washington

- Contact:

Re: Size 2 Martin build coming late October

"The large print giveth, and the small print taketh away." — Tom Waits

__________________________________

http://www.patfosterguitars.com

__________________________________

http://www.patfosterguitars.com

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: Size 2 Martin build coming late October

Well, here is the completion of the binding - doing the back.

The back purfling is just a simple b/w combo with the black about twice as wide as the white. So I used sanded down to about .012 holly veneer and some fairly thick black veneer that I had. I just cut 2 lines of each with a straightedge and a utility knife.

So, for starters, I just brushed glue in the purfling channel and pressed a holly strip in

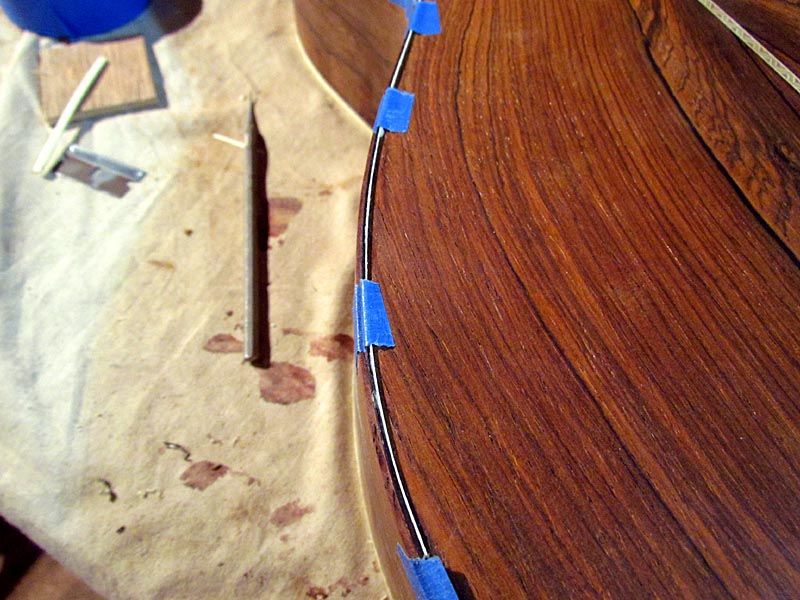

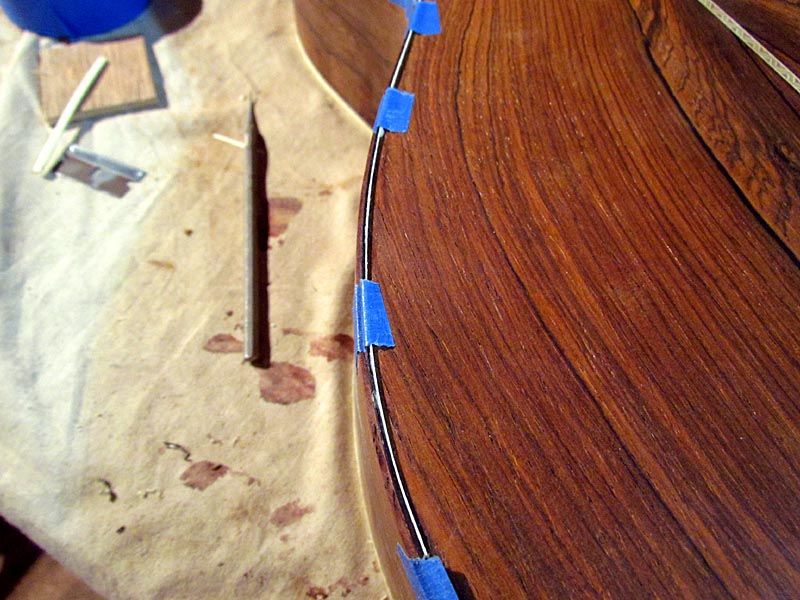

Here it is in place. since it is so thin and flexible, I only needed to tape the ends. The black strip is ready to go

So then I brushed on another layer of glue and layed on the black strip. After I taped the end even with the holly, I just wrapped around and taped it every so often

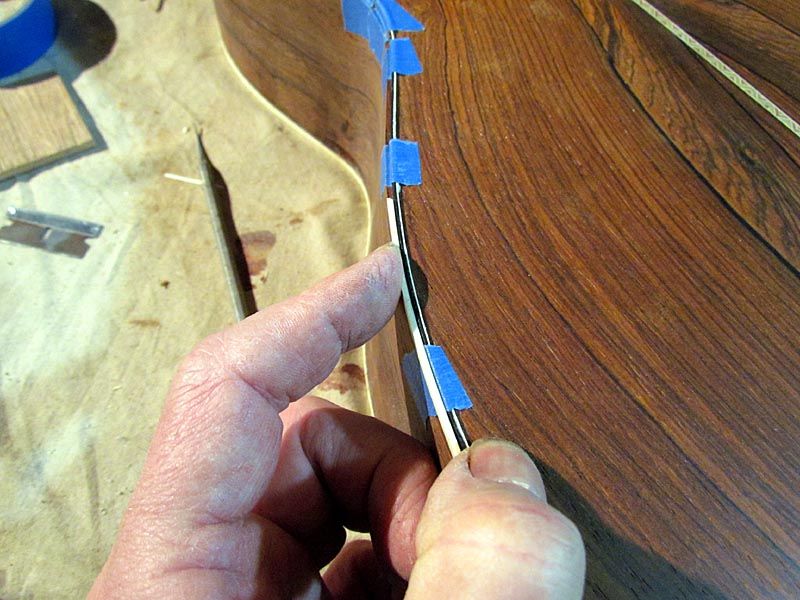

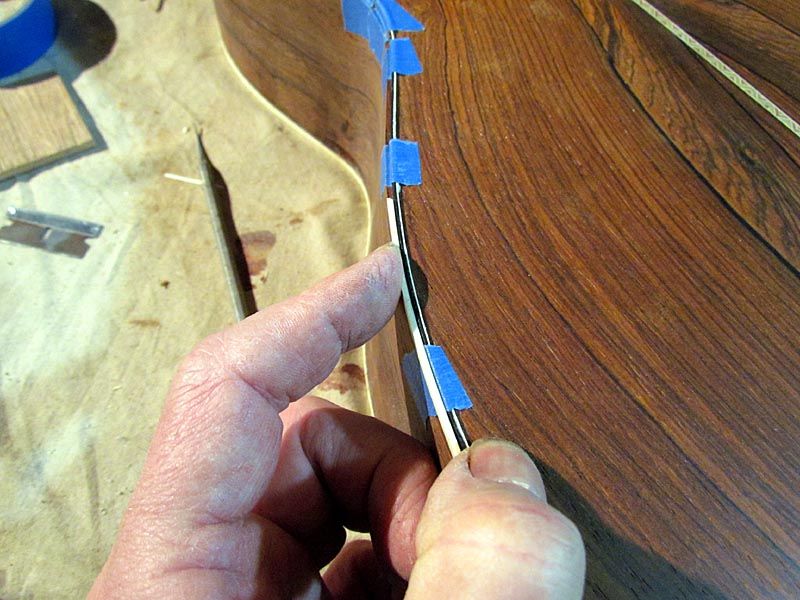

A closer look

Then I did the other half.

Here is just checking a piece of the ivoroid binding to see how well it fits

Looks like it will fit perfectly....

....so I started brushing on the B-72 glue, and putting on the ivoroid

It only took about a minute or so to glue and tape the ivoroid binding in place

So, while that glue was drying, I started cleaning up the top binding and purfling with a scraper

Just kinda rough cleaned so you can see the effect

And the back cleaned up a bit to show how that looks

Still needs some final cleaning, but I am happy with how it came out

Next I gotta do the neck joint

G

The back purfling is just a simple b/w combo with the black about twice as wide as the white. So I used sanded down to about .012 holly veneer and some fairly thick black veneer that I had. I just cut 2 lines of each with a straightedge and a utility knife.

So, for starters, I just brushed glue in the purfling channel and pressed a holly strip in

Here it is in place. since it is so thin and flexible, I only needed to tape the ends. The black strip is ready to go

So then I brushed on another layer of glue and layed on the black strip. After I taped the end even with the holly, I just wrapped around and taped it every so often

A closer look

Then I did the other half.

Here is just checking a piece of the ivoroid binding to see how well it fits

Looks like it will fit perfectly....

....so I started brushing on the B-72 glue, and putting on the ivoroid

It only took about a minute or so to glue and tape the ivoroid binding in place

So, while that glue was drying, I started cleaning up the top binding and purfling with a scraper

Just kinda rough cleaned so you can see the effect

And the back cleaned up a bit to show how that looks

Still needs some final cleaning, but I am happy with how it came out

Next I gotta do the neck joint

G

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: Size 2 Martin build coming late October

Well, since I am trying to make this guitar as close to the original as possible, I gotta do a dovetail neck joint. Now, I ain't never ever even considered this before, so this is jumping into the deep end of the pool for me

I thought maybe I could hand cut it, but I have reset necks on these old Martins, and the dovetail is clearly routed in, soo....

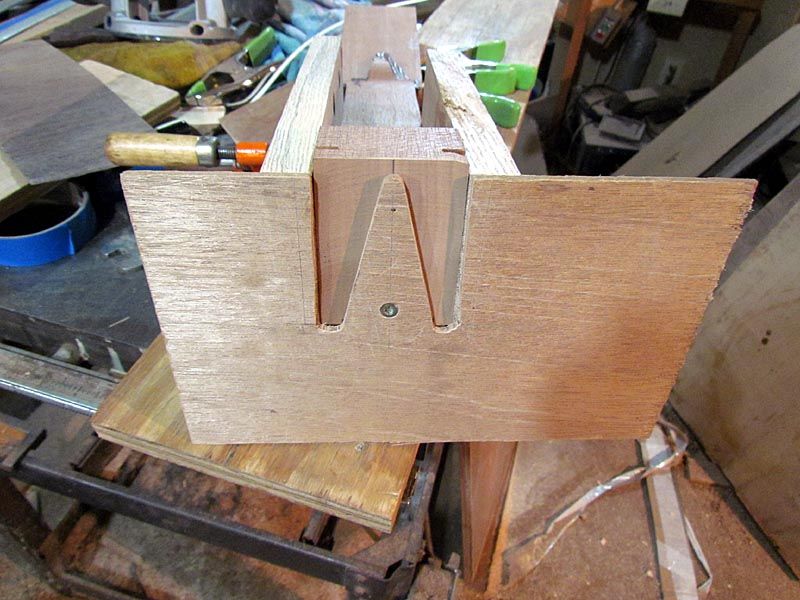

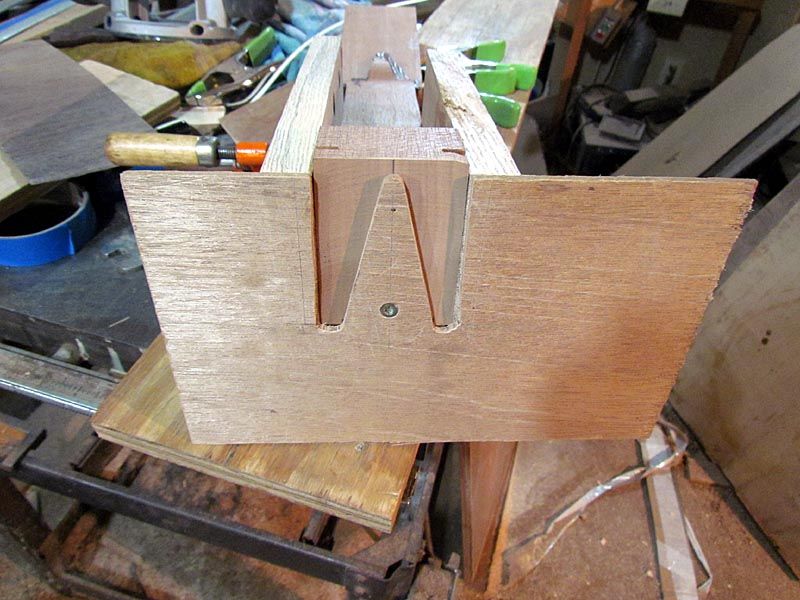

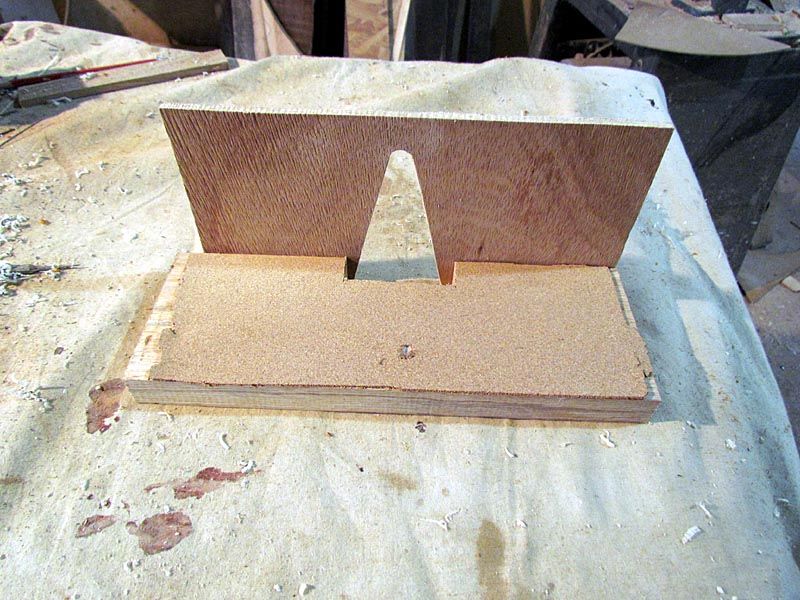

I don't have one of those Stew Mac dovetail routing templates, but figgured I could maybe make one up kinda quick. I have some 1/4" thick acrylic and thought that might be the way to go, but since I had no idea how to size it correctly, I decided to make a rough one out of scrap 1/4" ply just to practice a bit. Well, that worked surprisingly OK, so I decided to screw the acrylic and just use the plywood one. I did a bunch of test cuts on scrap first, but here it is attached onto the butt end of my neck

In the vise, ready to go

And my router ready to go

So here it is after the "white knuckle" routing

And with the template removed

Just a bit of cleanup and it looks like it should do the job. Notice that I did the neck first. I figured it would be simpler to redo a buggered up neck if my system went south, rather than build a new box

But now it is time to grit my teeth and tackle the box.

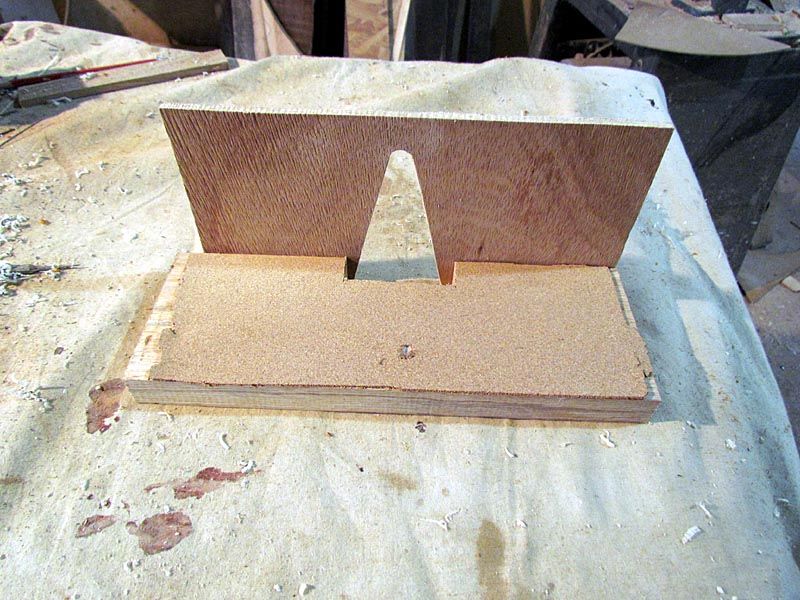

Here is the body template that I made

And here it is clamped to the box and getting squared up

Now, I spent a bunch of time making sure all was lined up well and square before I got the nerve to fire up the router

Here it is ready to go

I was gonna cobble up something to clamp the body to the bench, but a friend came over about that time, so I just had him hold it

And here it is all routed

Only took about a half a minute to route and it went real slick Happy camper here

Happy camper here

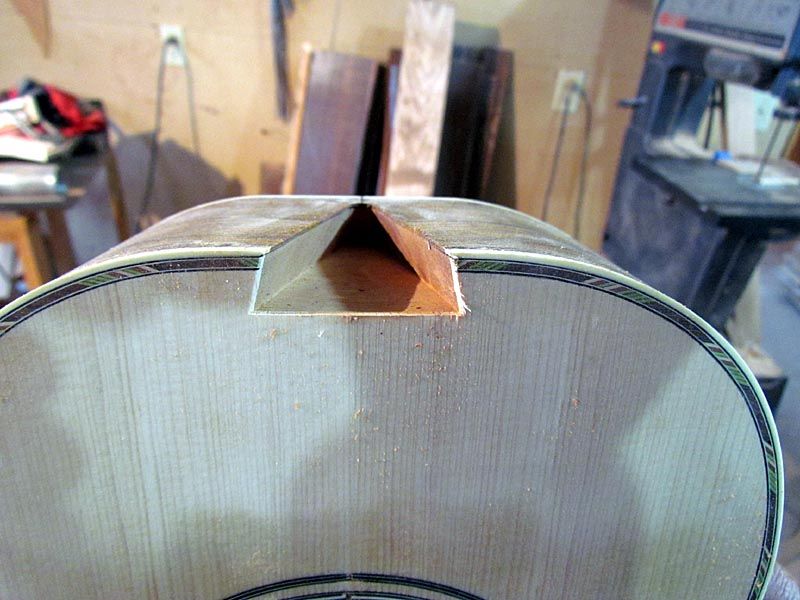

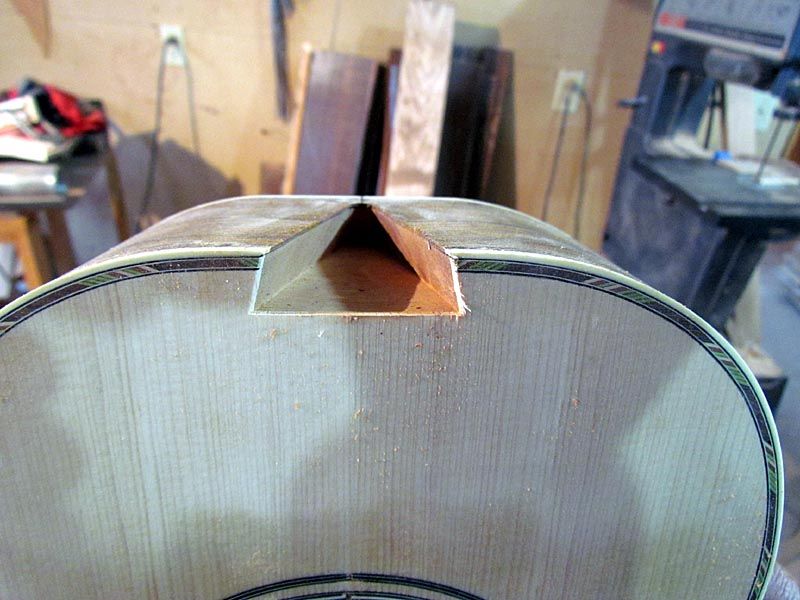

So I sized everything so it was a too tight fit. Actually the neck initially sat about 3/16" high. That way I could gradually sand off bits from the edge of the dovetail to really fine tune the fit. Here it is after final fitting

It sits about 1/64" high, but clamped tightly, it just goes down flush. And looks like the neck setback is right where it is supposed to be, too.

So my first dovetail neck joint, kinda done "seat-of-the-pants" style, but it came out perfect

Now just easy stuff to do.

Thanks for looking,

G

I thought maybe I could hand cut it, but I have reset necks on these old Martins, and the dovetail is clearly routed in, soo....

I don't have one of those Stew Mac dovetail routing templates, but figgured I could maybe make one up kinda quick. I have some 1/4" thick acrylic and thought that might be the way to go, but since I had no idea how to size it correctly, I decided to make a rough one out of scrap 1/4" ply just to practice a bit. Well, that worked surprisingly OK, so I decided to screw the acrylic and just use the plywood one. I did a bunch of test cuts on scrap first, but here it is attached onto the butt end of my neck

In the vise, ready to go

And my router ready to go

So here it is after the "white knuckle" routing

And with the template removed

Just a bit of cleanup and it looks like it should do the job. Notice that I did the neck first. I figured it would be simpler to redo a buggered up neck if my system went south, rather than build a new box

But now it is time to grit my teeth and tackle the box.

Here is the body template that I made

And here it is clamped to the box and getting squared up

Now, I spent a bunch of time making sure all was lined up well and square before I got the nerve to fire up the router

Here it is ready to go

I was gonna cobble up something to clamp the body to the bench, but a friend came over about that time, so I just had him hold it

And here it is all routed

Only took about a half a minute to route and it went real slick

So I sized everything so it was a too tight fit. Actually the neck initially sat about 3/16" high. That way I could gradually sand off bits from the edge of the dovetail to really fine tune the fit. Here it is after final fitting

It sits about 1/64" high, but clamped tightly, it just goes down flush. And looks like the neck setback is right where it is supposed to be, too.

So my first dovetail neck joint, kinda done "seat-of-the-pants" style, but it came out perfect

Now just easy stuff to do.

Thanks for looking,

G

- DaveWhite

- Posts: 1026

- Joined: Mon Nov 10, 2008 4:01 pm

- Include Off Topic: Yes

- Location: Hughenden Valley, Buckinghamshire, England

- Contact:

Re: Size 2 Martin build coming late October

Grant,

Great stuff again - especially the DIY dovetail joint. That's going to be one very pretty looking and sounding instrument.

Great stuff again - especially the DIY dovetail joint. That's going to be one very pretty looking and sounding instrument.

Dave White

De Faoite Stringed Instruments

". . . the one thing a machine just can't do is give you character and personalities and sometimes that comes with flaws, but it always comes with humanity" Monty Don talking about hand weaving, "Mastercrafts", Weaving, BBC March 2010

De Faoite Stringed Instruments

". . . the one thing a machine just can't do is give you character and personalities and sometimes that comes with flaws, but it always comes with humanity" Monty Don talking about hand weaving, "Mastercrafts", Weaving, BBC March 2010

Re: Size 2 Martin build coming late October

Grant,

Congrats on the dovetail joint! I love your style.

You got me wanting to try as well. Very inspiring.

Please continue posting, even after this one is finished.

Thanks,

_Mike

Congrats on the dovetail joint! I love your style.

You got me wanting to try as well. Very inspiring.

Please continue posting, even after this one is finished.

Thanks,

_Mike

- DaveAnderson

- Posts: 1123

- Joined: Fri Nov 21, 2008 10:18 am

- Include Off Topic: Yes

- Location: Clearwater,Fl.

Re: Size 2 Martin build coming late October

Nice job on the dovetail Grant. She's going to be a real beauty !!

Anderson Guitars

Clearwater,Fl.

Clearwater,Fl.

-

Matthew Jenkins

- Posts: 405

- Joined: Tue Jan 20, 2009 4:47 am

Re: Size 2 Martin build coming late October

Yep - that sure does look pretty.

I love how the purfling gives a sort of abalone effect but in a much more stylish way.

Great stuff!

I love how the purfling gives a sort of abalone effect but in a much more stylish way.

Great stuff!

Re: Size 2 Martin build coming late October

Wow! What a great "caveman" piece of work!  Great nerves, Grant. And great nerves your friend must have had to hold that body steady. I can just imagine the grunted conversation that went on as you did the routing.

Great nerves, Grant. And great nerves your friend must have had to hold that body steady. I can just imagine the grunted conversation that went on as you did the routing.

Jim

Jim

"When people hear good music, it makes them homesick for something they never had and never will have." -- Edgar Watson Howe