Jim, yes, this is a time consuming. Basically sorta making frets from scratch, kinda like building a guitar starting with logs

What you are doing is just inlaying these bars of metal into the fingerboard and leaving enough metal sticking up so you can shape it into a fret. But it is interesting, and actually kinda rewarding when you get done. Oh, and while I do have the time, the expertise will come after a couple more fingerboards

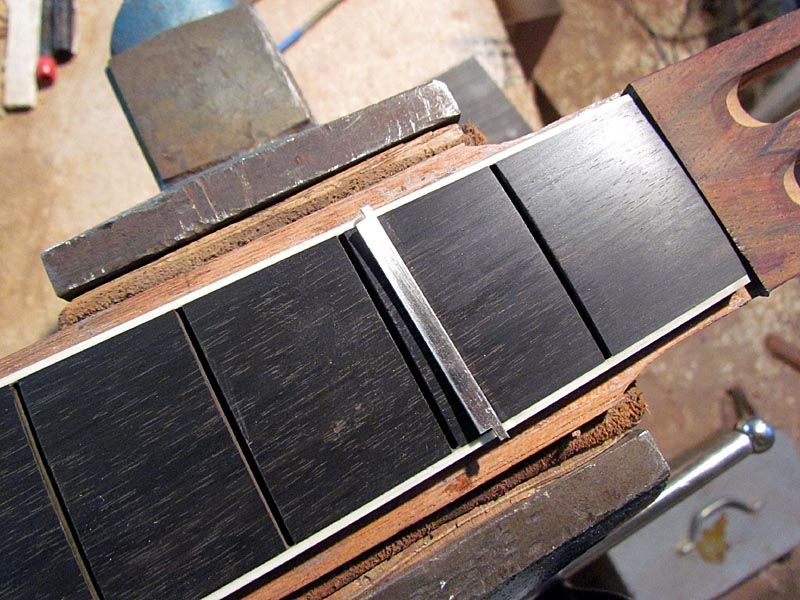

So one of the additional things that one discovers is that you must not have too tight of a fit with bar frets. On standard frets, just the barbs on the tangs push against the sides of the slots and they sink into the wood. With bar frets, the entire face of the fret pushes against the wood and the wood does not give. The trick seems to be to thin the fret until you can almost seat it by hand, and just a couple of taps will finish it off. So how do I know? Well those last couple of frets that I put in were giving the fingerboard tongue a significant back bow that was difficult to flatten out. So I ended up removing the last 3 frets and thinning them down. The fingerboard tongue still backbows a bit because it is unsupported, but I can push it flat, so I think all will be OK. Hopefully the main neck part will be fine. For sure, it will not need a truss rod or any other stiffener to prevent an upbow.

So here is the fingerboard with all the frets in place

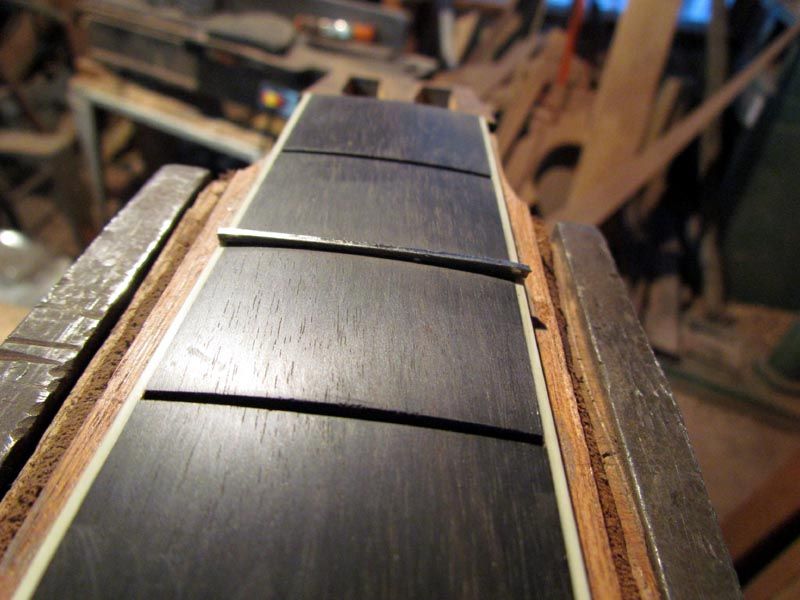

And here it is taped up so I can shape the frets to the fingerboard radius

So to shape the frets, I took a reject ebony binding strip and sanded it down to a tad over .040" thickness. I cut it into 2 pieces and glued them to a file

These will serve as thickness guide rails that will ride on the curvature of the fingerboard as the frets are shaped

So here you can see a shaped fret (closest to the file, compared to those yet to be shaped

So I just continued the process on the rest of the frets. It took about 5 minutes or so on each fret. Actually I worked on several frets at a time because they heated up quite a bit from filing and I had to give them time to cool

So here they are pretty much filed and the tape removed

You can probably see that the frets, especially near the fingerboard end, need a bit more shaping, especially on the treble side

So I marked the tops with black marker and fine tuned the shape and checked for level. Took a bit of fiddling, but all came out decent. Then I used a regular fret crowning file and rounded the frets

Here, the ones closest to the nut have been done, the rest are still square-topped

Here, they have all been rounded off

Still some fine tuning and cleanup and polishing to do, but I will wait with that until after the neck is shaped.

As for time, it took 3 or 4 hours to cut and instal the frets, and I suppose I messed with the shaping and such for another couple of hours. I learned a lot in the process, so the next time will probably be neater and a bit faster. I kinda enjoyed doing this....makes regular fretting seem kinda bland

So next, I will carve the neck to shape.

Stay tuned,

G