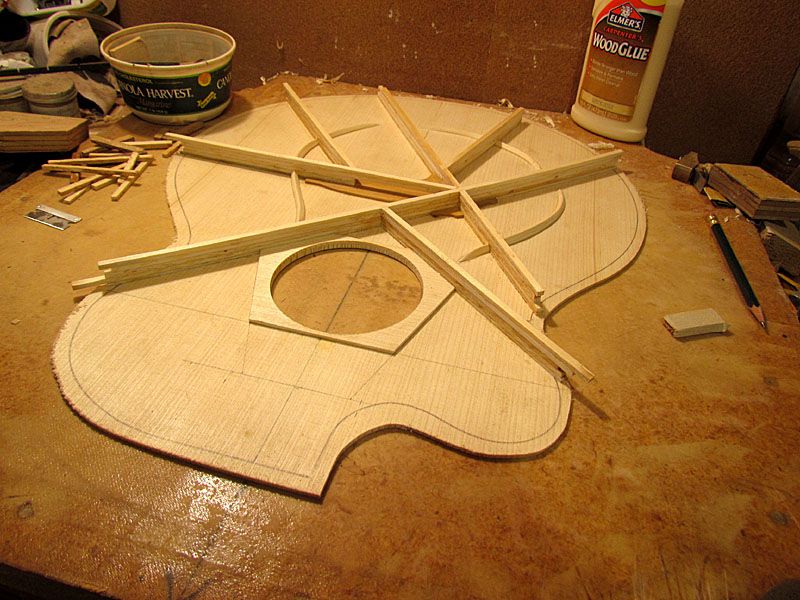

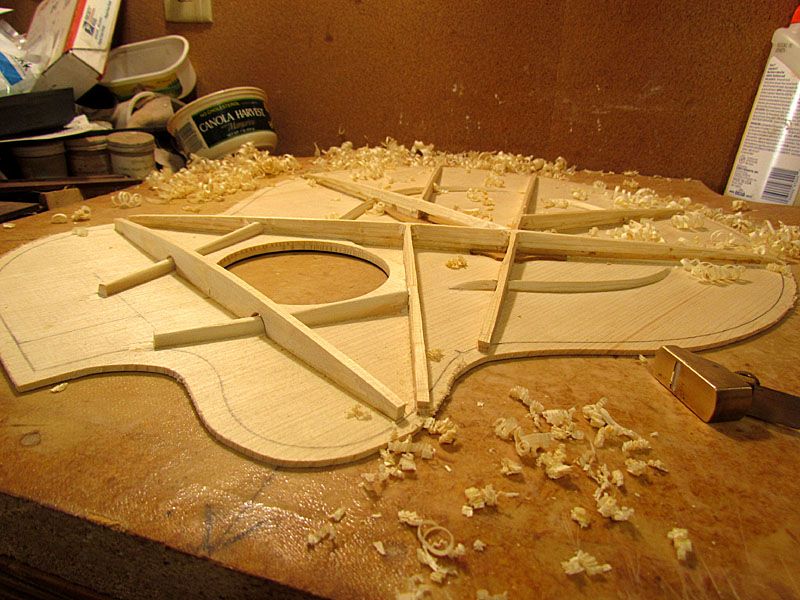

OK, finished up the top bracing.

Here are the rest of the laminations glued in on the braces

The A-frame upper braces and the upper cross brace are not laminated, but are solid wood

Here are the A-frame braces being glued

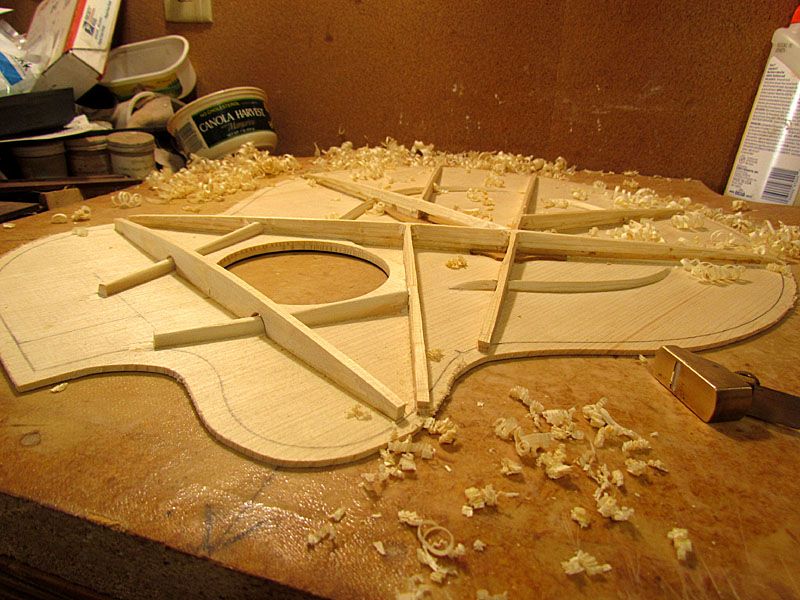

Before I glue the upper cross brace, I need to rough profile the laminated braces. I do this with a shop modified router bit that tapers the sides of the braces

Look closely to see the slightly tapered cutter

Here is the result

The brace intersections will get cleaned up later by hand

After shaping the A-frame braces, I glue in the upper cross brace

Notice that there are cutouts to let the A-frame braces pass under the upper cross brace

Next I do more brace shaping, sloping the brace heights and cleaning up the intersections

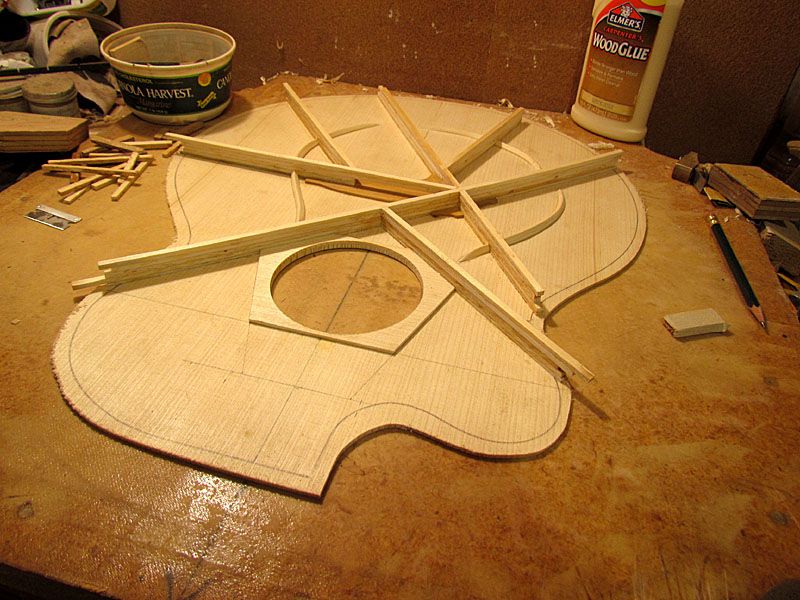

Then it is on to rough sanding and fine tuning until they look like this

Just some fine sanding and a bit of cleanup to go.

I mentioned earlier that I plan to use the laminated linings similar to what Colin does. Here is my version

After doing this, I do not intend to go back to the kerfed linings. This is waaaay better and looks better, too.

Thanks for looking in.

G