In the spirit of your "Organic Soundports" build maybe you should start training up some termites to "pre-process" your back braces

My revised XX back bracing

- DaveWhite

- Posts: 1026

- Joined: Mon Nov 10, 2008 4:01 pm

- Include Off Topic: Yes

- Location: Hughenden Valley, Buckinghamshire, England

- Contact:

Re: My revised XX back bracing

Grant,

In the spirit of your "Organic Soundports" build maybe you should start training up some termites to "pre-process" your back braces As always your ideas are very interesting and fresh and keep all of us young.

As always your ideas are very interesting and fresh and keep all of us young.

In the spirit of your "Organic Soundports" build maybe you should start training up some termites to "pre-process" your back braces

Dave White

De Faoite Stringed Instruments

". . . the one thing a machine just can't do is give you character and personalities and sometimes that comes with flaws, but it always comes with humanity" Monty Don talking about hand weaving, "Mastercrafts", Weaving, BBC March 2010

De Faoite Stringed Instruments

". . . the one thing a machine just can't do is give you character and personalities and sometimes that comes with flaws, but it always comes with humanity" Monty Don talking about hand weaving, "Mastercrafts", Weaving, BBC March 2010

- Marcus McGuinness

- Posts: 265

- Joined: Tue Sep 22, 2009 2:54 am

- Include Off Topic: Yes

- Location: Málaga, Spain

Re: My revised XX back bracing

Is it because it's the New Year or because you've just turned 70 that your getting so creative?

Mac

Mac

- Fred Blom

- Posts: 556

- Joined: Tue Jan 20, 2009 12:07 pm

- Include Off Topic: Yes

- Location: Montevideo, MN

Re: My revised XX back bracing

Grant, I keep visiting this thread to simply admire your work and wonder (as with "awe") at your creative mind. What would this do on the long legs of the X-brace for the top?

Fred Blom

Remember the joy of the journey

Remember the joy of the journey

- garydemos

- Posts: 140

- Joined: Sat Aug 23, 2008 6:36 pm

- Include Off Topic: Yes

- Location: Hilliard, OH

- Contact:

Re: My revised XX back bracing

Those are cool looking trusses Grant. FYI I stole your idea of cross bracing the back but since I'm a lot more lazy than you I simply cross braced the back the same way I cross brace the top except without any tone bracing - just the single cross bracing only. I've done this on a couple classicals and 2 smaller steel string guitars (LG-1 copies). I've found that the back is less stiff and resonates very nicely - it enhances the bass on these guitars. My main reason for doing it was as you state it reduces the grain-locking affect of perpendicular cross bracing. I suppose that a dread would need the double X-brace as you have been doing but for smaller bodied guitars the single X-brace seems to be working fine for me.

- Eben

- Chairman Emeritus

- Posts: 6152

- Joined: Thu Aug 21, 2008 9:58 am

- Include Off Topic: Yes

- Location: Lummi Bay, WA

- Contact:

Re: My revised XX back bracing

Grant and I came to the double X back brace plan at about the same time, but man, yours are far finer, G! I've not yet adopted the laminated method, but I'm gonna try it now!

E

E

- Bilbert

- Site Admin

- Posts: 929

- Joined: Thu Aug 21, 2008 8:09 am

- Include Off Topic: Yes

- Location: Tampa, FL

Re: My revised XX back bracing

Well color me impressed, but not surprised...........

That is the coolest thing I've seen in quite some time!

I, too, found myself thinking: "that might work great on a guitar TOP" - any thoughts, G?

BTW - beautiful Coco back!

B

That is the coolest thing I've seen in quite some time!

I, too, found myself thinking: "that might work great on a guitar TOP" - any thoughts, G?

BTW - beautiful Coco back!

B

Bill Bertolino

I'm watchin' TV in the window of a furniture store................. T Waits.

I'm watchin' TV in the window of a furniture store................. T Waits.

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: My revised XX back bracing

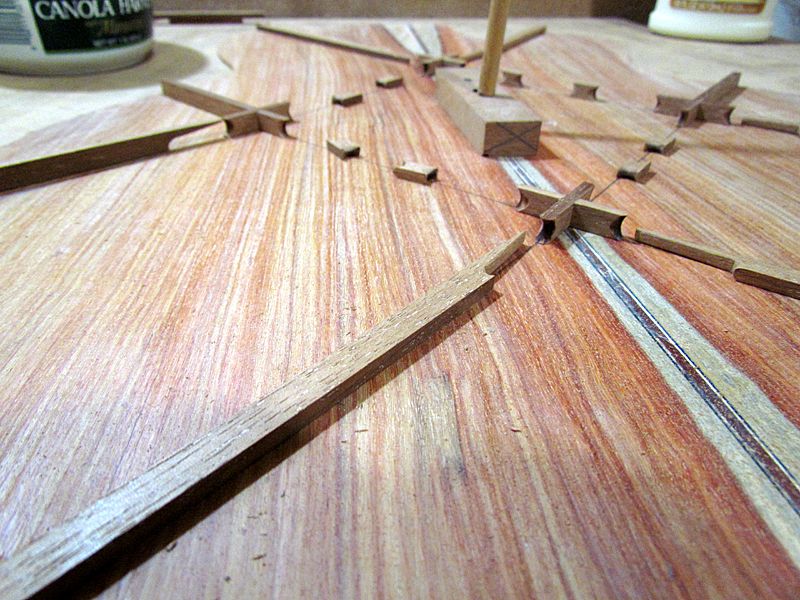

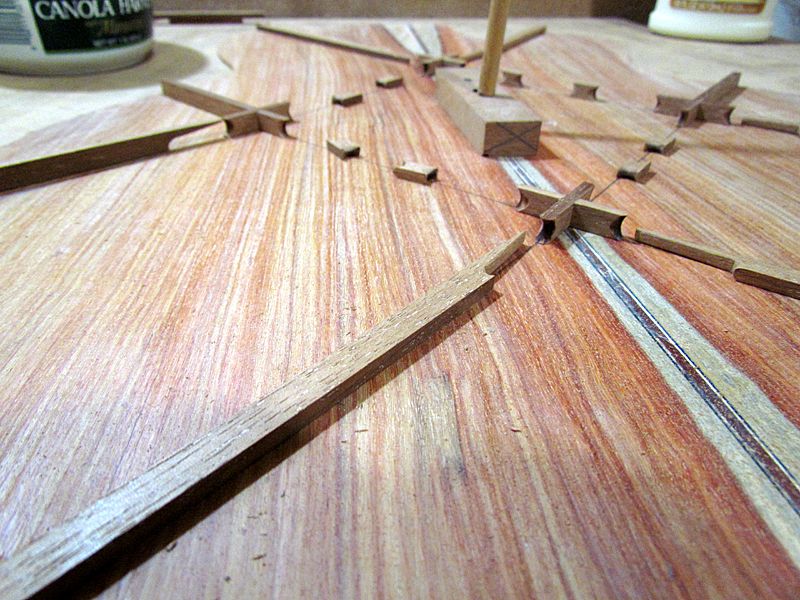

Here is a better look at the components that make up the second layer of laminations.

Remember that there is a first layer that is 1/8" thick that goes ofer the whole xx pattern. The short X segments at the intersections are notched together. Notice how I have roughly sanded a concave end on the parts that will be at the ends of the open spaces. Some of the parts here are shown laying flat so you can see the shape better

Another view

This is on an African tulip back AKA pau rosa.

Hope this helps to explain what I do. This is the third back I have done this on. I make up all of the parts first and the glue-up of the 4 layers goes fairly fast.

G

Remember that there is a first layer that is 1/8" thick that goes ofer the whole xx pattern. The short X segments at the intersections are notched together. Notice how I have roughly sanded a concave end on the parts that will be at the ends of the open spaces. Some of the parts here are shown laying flat so you can see the shape better

Another view

This is on an African tulip back AKA pau rosa.

Hope this helps to explain what I do. This is the third back I have done this on. I make up all of the parts first and the glue-up of the 4 layers goes fairly fast.

G

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: My revised XX back bracing

OK, I am going to show this again in more detail with measurements and how I make all of the parts. Since I will be doing it for my bar fret builds, I will put the process in that thread. Should have the details there by Monday night.

G

G