Oh my, them's gonna be stunners, indeed!

E

2 new bar fret guits, sound file added

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: 2 new bar fret guits

Today's installment, as promised.

Fret Slots

Obviously, these are way different than the slots needed for regular fretwire. First, they need to be wider to accommodate the thickness of the bar stock. They also need to be flat bottomed since the bar frets seat directly on the bottom of the slot rather than following the profile of the fingerboard surface as in modern fretwire. So, I cut the slots on a table saw with a sled and a home made template. But first I need a blade that will cut the proper slot width. I want a snug, but not a forced fit, and I like the slot to start a bit tighter to allow me to hone a few thousands off the faces of the frets to get just the right fit.

I had honed down the sides of the teeth on a 7 1/2 Diablo thin kerf blade (which off the shelf cuts a sloppy 1/16" slot) to get a good fit for the LMI bar fret stock, which is .056" thick. These frets are a bit thicker, so I need to prepare another blade.

So, I start with a slightly used blade and rub both sides on a flat silicon carbide grinding wheel

This polishes the sides of the carbide tips and also trues up the irregularities in this (cheap) blade. I do both sides until I am satisfied with the thickness of the teeth. In this case, I aimed for about .o58"

Then I mount the blade with 5" diameter blade stabilizers

And make a test cut to check the fret fit.

I do test cuts using my sled to get the slot depth set. Then I attach my slotted template (shop made) to the blank with double faced tape. The slots in the template register with a metal fin in my sled (red arrow) and I cut the slots

another view

And here is the result

And here is a shot of the neck blanks and blocks

One about ready to go and the other needing peghead ears and the mortise and tenon cut.

Thanks for looking, comments and questions appreciated.

G

Fret Slots

Obviously, these are way different than the slots needed for regular fretwire. First, they need to be wider to accommodate the thickness of the bar stock. They also need to be flat bottomed since the bar frets seat directly on the bottom of the slot rather than following the profile of the fingerboard surface as in modern fretwire. So, I cut the slots on a table saw with a sled and a home made template. But first I need a blade that will cut the proper slot width. I want a snug, but not a forced fit, and I like the slot to start a bit tighter to allow me to hone a few thousands off the faces of the frets to get just the right fit.

I had honed down the sides of the teeth on a 7 1/2 Diablo thin kerf blade (which off the shelf cuts a sloppy 1/16" slot) to get a good fit for the LMI bar fret stock, which is .056" thick. These frets are a bit thicker, so I need to prepare another blade.

So, I start with a slightly used blade and rub both sides on a flat silicon carbide grinding wheel

This polishes the sides of the carbide tips and also trues up the irregularities in this (cheap) blade. I do both sides until I am satisfied with the thickness of the teeth. In this case, I aimed for about .o58"

Then I mount the blade with 5" diameter blade stabilizers

And make a test cut to check the fret fit.

I do test cuts using my sled to get the slot depth set. Then I attach my slotted template (shop made) to the blank with double faced tape. The slots in the template register with a metal fin in my sled (red arrow) and I cut the slots

another view

And here is the result

And here is a shot of the neck blanks and blocks

One about ready to go and the other needing peghead ears and the mortise and tenon cut.

Thanks for looking, comments and questions appreciated.

G

- Eben

- Chairman Emeritus

- Posts: 6152

- Joined: Thu Aug 21, 2008 9:58 am

- Include Off Topic: Yes

- Location: Lummi Bay, WA

- Contact:

Re: 2 new bar fret guits

How deep are ya cutting those, G? Hard for my old orbs to discern!

E

E

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: 2 new bar fret guits

about .11" or soEben wrote:How deep are ya cutting those, G? Hard for my old orbs to discern!

E

G

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: 2 new bar fret guits

Well, I have been trying to do a bit on these every day or so. Yesterday I joined the tops...nothing really to show, just blue tape.

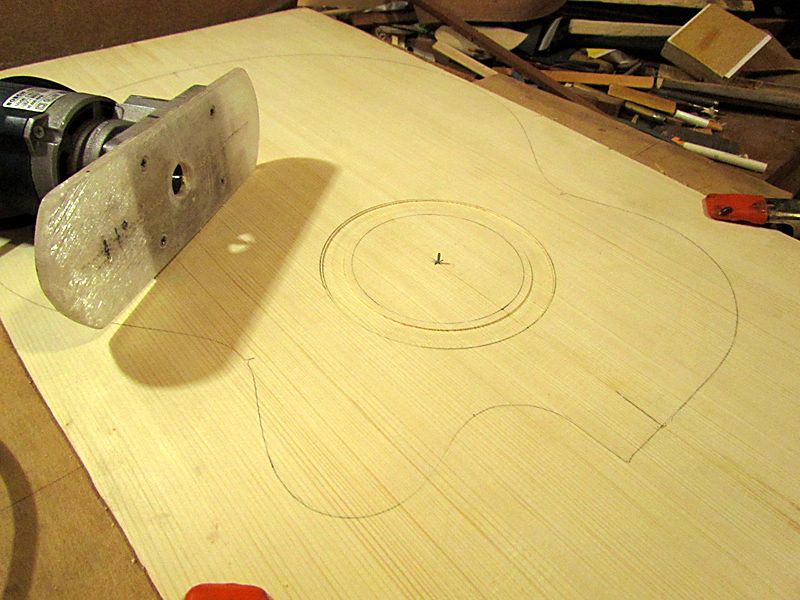

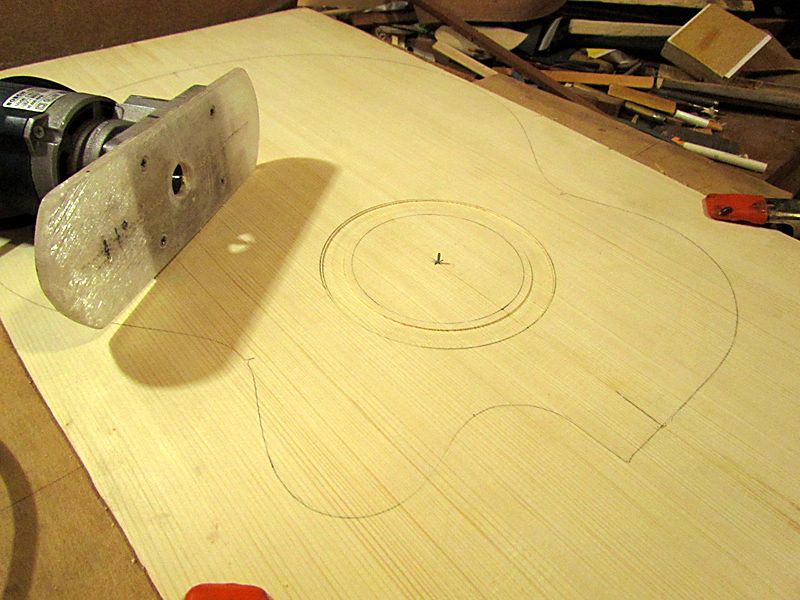

So today I started the rosettes. First, I routed the channels

I am doing the bark thing again, so this time I ran a big strip of birch bark through the thickness sander. Got it cleaned of and down to a tad under 1/16" thick. then I gave it a coat of shellac on both sides

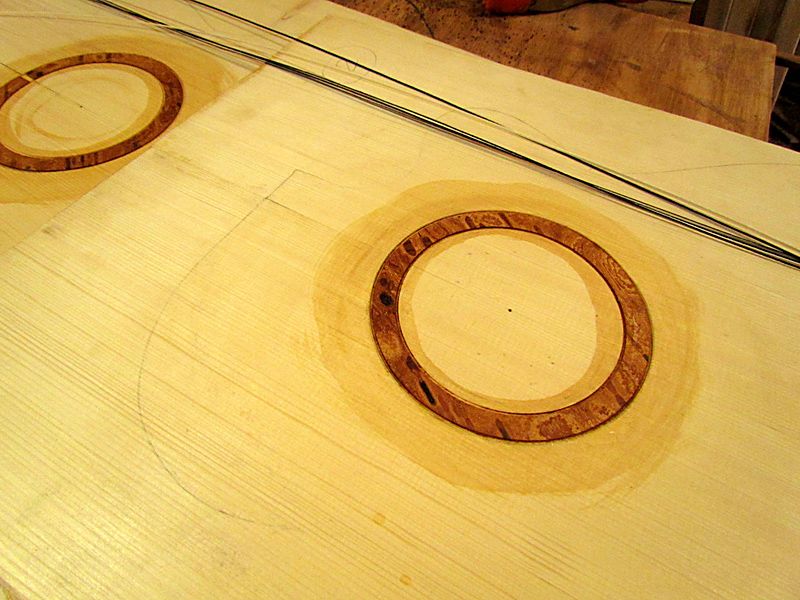

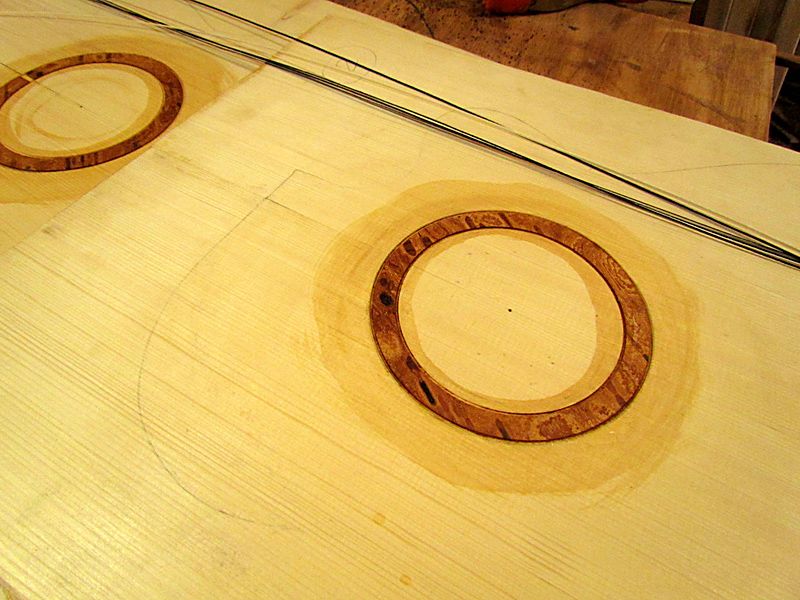

Next step was to cut a couple of bark rings with the small router

After getting a good dry fit....

....I glued them in and put a flat caul and a heavy weight on top

Tomorrow I will route a narrow channel inside and out and install b/w/b purflings. Then I can final sand the tops, cut the outline, and they will be ready to brace.

Thanks for looking,

G

So today I started the rosettes. First, I routed the channels

I am doing the bark thing again, so this time I ran a big strip of birch bark through the thickness sander. Got it cleaned of and down to a tad under 1/16" thick. then I gave it a coat of shellac on both sides

Next step was to cut a couple of bark rings with the small router

After getting a good dry fit....

....I glued them in and put a flat caul and a heavy weight on top

Tomorrow I will route a narrow channel inside and out and install b/w/b purflings. Then I can final sand the tops, cut the outline, and they will be ready to brace.

Thanks for looking,

G

Re: 2 new bar fret guits

Looking great Grant. Glad you're in the shop and posting. Nice top too. T

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: 2 new bar fret guits

Thanks for the comments, Tim. These are a couple of the last of my close grain white spruce tops from a log I processed about 12 years ago. Sure wish I had a bunch more of that, but I sold off a bunch of it waaay too cheap

So, finished the rosettes today, first routed 1/16" channels inside and out and cut some black and white veneer strips. gave everything a light coat of shellac to seal the grain

Then I laid in the veneer lines dry. Had to hand sand them a tad to get 3 layers to fit in the channels

Then I flooded them with CA

After some hand sanding to roughly level things (can't scrape or plane the bark) I ran the tops through the thickness sander

All done

I did have one small problem...about an inch of one of the b/w/b lines did not get seated deep enough and it sanded through So will have to reroute a short section and splice in some more veneer strips

So will have to reroute a short section and splice in some more veneer strips

Guess I had better show that process.

G

So, finished the rosettes today, first routed 1/16" channels inside and out and cut some black and white veneer strips. gave everything a light coat of shellac to seal the grain

Then I laid in the veneer lines dry. Had to hand sand them a tad to get 3 layers to fit in the channels

Then I flooded them with CA

After some hand sanding to roughly level things (can't scrape or plane the bark) I ran the tops through the thickness sander

All done

I did have one small problem...about an inch of one of the b/w/b lines did not get seated deep enough and it sanded through

Guess I had better show that process.

G

- Dennis Leahy

- Dishwasher

- Posts: 7082

- Joined: Thu Aug 21, 2008 1:59 am

- Include Off Topic: Yes

- Location: looking for a place to live