2 new bar fret guits, sound file added

- Dennis Leahy

- Dishwasher

- Posts: 7082

- Joined: Thu Aug 21, 2008 1:59 am

- Include Off Topic: Yes

- Location: looking for a place to live

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: 2 new bar fret guits

Well, that's the next plan, take it outside in the fresh air tomorrow. Because.....I got one more fret clipped and then my brand new $50 cutter brokeDennis Leahy wrote:I wonder if Dremel cut-off wheels will cut it.

Need to look for a heavier duty unit

G

-

johnparchem

- Site Admin

- Posts: 969

- Joined: Sat Oct 02, 2010 8:26 am

- Include Off Topic: Yes

- Location: Seattle

- Contact:

Re: 2 new bar fret guits

If you are careful, it seems like a hack saw would make quick work of them, I think you can get the cut closer than I am seeing with the clippers

Re: 2 new bar fret guits

I agree with Dennis, the dremel with a cut off wheel would make short work of them. Need a steady hand . I've done a couple like that and gotten close enough to finish up with a file.

Mike

Mike

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: 2 new bar fret guits

You all probably know the truth here....just another example of me diving in without thinking things through  I cut the frets initially just roughly to length not thinking of the eventual hardness possibly being a problem when it came time to finish the ends (well, the thought probably crossed my mind, but I ignored it). So here I am needing to pry my sorry ass out of the problem. Not the first time and certainly won't be the last

I cut the frets initially just roughly to length not thinking of the eventual hardness possibly being a problem when it came time to finish the ends (well, the thought probably crossed my mind, but I ignored it). So here I am needing to pry my sorry ass out of the problem. Not the first time and certainly won't be the last

So, yes, the dremel cut off wheel will likely save my butt. But if I am going to make this a viable deal, I will have to do something differently. For the present, I am mainly trying to minimize operations that could create substantial airborne Beryllium copper dust. Clipping, sawing, and filing are not much of an issue....grinding is. So, for now, I will do the dremel thing outside with dust mask, face shield and a decent breeze at my back. I will eventually have a dedicated work station using my old dust collector exiting directly outside through the wall. So I would clean up fret ends to almost exact length BEFORE heat treating and installation. Then the minor filing and leveling, done over a downdraft table will not be an issue.

If this fret system DOES result in the sound improvement that I think it will, and I end up offering sets of frets, I would supply them already finished to that point (top radius and lengths ready to go) so the issues would already be solved.

The other thing I will be doing is backing off on the heat treating a tad. This round was just a guess, with my main concern being that I might not get them hard enough. Well, this set will put stainless steel to shame....no need for that

Supposed to be 68 degrees today, so working outside a bit will be fun. And then, maybe bend a set of sides. Gotta get building a box for this one.

G

So, yes, the dremel cut off wheel will likely save my butt. But if I am going to make this a viable deal, I will have to do something differently. For the present, I am mainly trying to minimize operations that could create substantial airborne Beryllium copper dust. Clipping, sawing, and filing are not much of an issue....grinding is. So, for now, I will do the dremel thing outside with dust mask, face shield and a decent breeze at my back. I will eventually have a dedicated work station using my old dust collector exiting directly outside through the wall. So I would clean up fret ends to almost exact length BEFORE heat treating and installation. Then the minor filing and leveling, done over a downdraft table will not be an issue.

If this fret system DOES result in the sound improvement that I think it will, and I end up offering sets of frets, I would supply them already finished to that point (top radius and lengths ready to go) so the issues would already be solved.

The other thing I will be doing is backing off on the heat treating a tad. This round was just a guess, with my main concern being that I might not get them hard enough. Well, this set will put stainless steel to shame....no need for that

Supposed to be 68 degrees today, so working outside a bit will be fun. And then, maybe bend a set of sides. Gotta get building a box for this one.

G

- whitespruce

- Site Admin

- Posts: 4367

- Joined: Thu Aug 21, 2008 6:53 am

- Include Off Topic: Yes

- Location: Northern Minnesota, USA

Re: 2 new bar fret guits

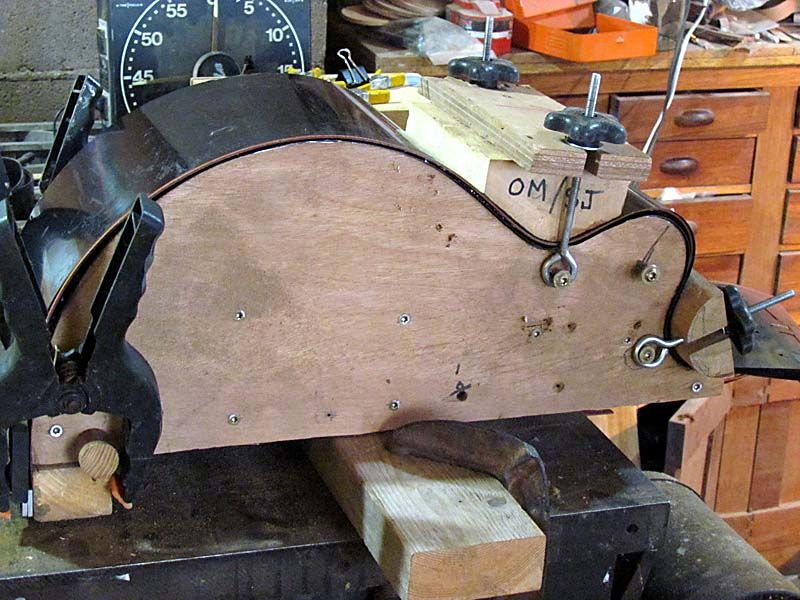

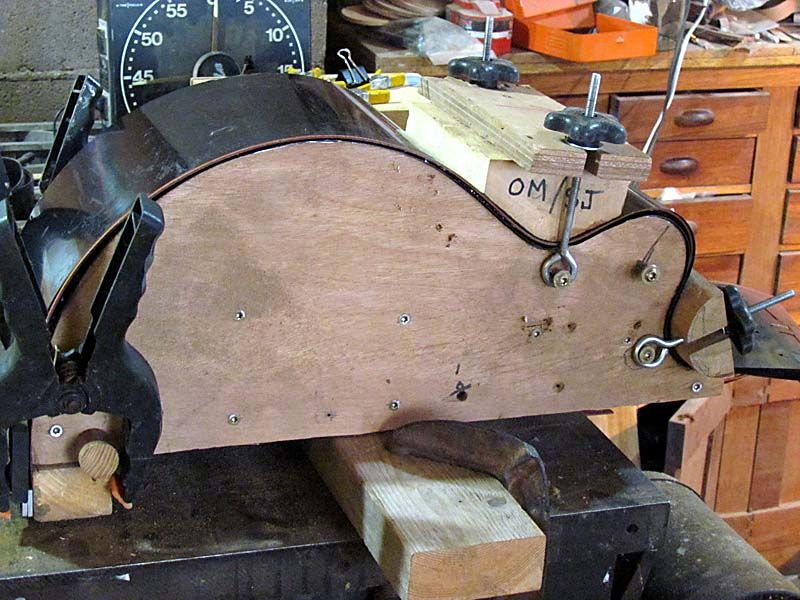

Well, the temps today were in the upper 60's, so I "suited up" and took the neck outside and did the dremel cut off wheel thing. Took less than 10 minutes and worked perfectly. Just a tiny bit left to file flush with the fingerboard.

Ron Miles was up for the afternoon, so we bent the sides for this one.

I just lightly sanded the dark coco "resin" to show that the wood color is still there.

So now I can move on with this one. The top is already braced, and the end blocks and top linings are made.

Stay tuned,

G

Ron Miles was up for the afternoon, so we bent the sides for this one.

I just lightly sanded the dark coco "resin" to show that the wood color is still there.

So now I can move on with this one. The top is already braced, and the end blocks and top linings are made.

Stay tuned,

G

Re: 2 new bar fret guits

Isn't that the way it aways goes? Make a plan... Buy the crap you need... Then after the fact find out you had the stuff to do it in the first place.

Sorry to hear you broke your $50 nippers Grant. Maybe it was a defect in the manufacturing and you can get a new pair...

Good to see you are back in shop getting on with life

Cheers,

Bob

Sorry to hear you broke your $50 nippers Grant. Maybe it was a defect in the manufacturing and you can get a new pair...

Good to see you are back in shop getting on with life

Cheers,

Bob

- Garry Hallam

- Posts: 1062

- Joined: Sun Aug 24, 2008 1:38 pm

- Include Off Topic: Yes

- Location: Saddleworth,England

Re: 2 new bar fret guits

Just thinking that You could cut them to approximate length before you heat treat them. would mean doing the fingerboard first.

You could also crown them to their profile before treatment too which would be less work once installed. lesser amount to work on the hardened material.

Garry

You could also crown them to their profile before treatment too which would be less work once installed. lesser amount to work on the hardened material.

Garry

Silly rule golden words make, practice practice makes perfect,

Perfect is a fault, and fault lines change - Michael Stipe

Perfect is a fault, and fault lines change - Michael Stipe