Well I took some time while the shop was warming up today to work on the neck. As I mentioned, this will be a V joint peghead, just like the original 1890 Martin that I am replicating has.

One nice thing about this style of neck is that I can use shorter "scraps" of mahogany that are too small for a regular neck. Only needed a 16" long piece for the neck shaft.

So I cut a blank and drew out the neck

Then I bandsawed it out

I was able to pick out a perfectly quartersawn offcut for this neck

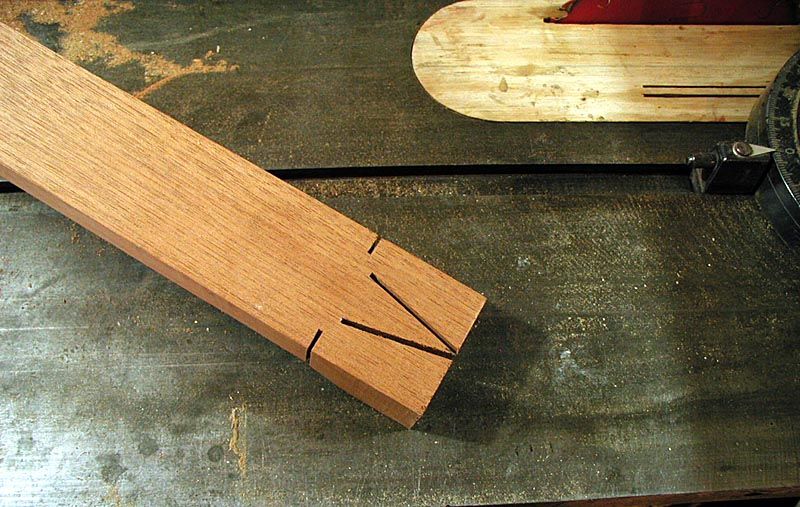

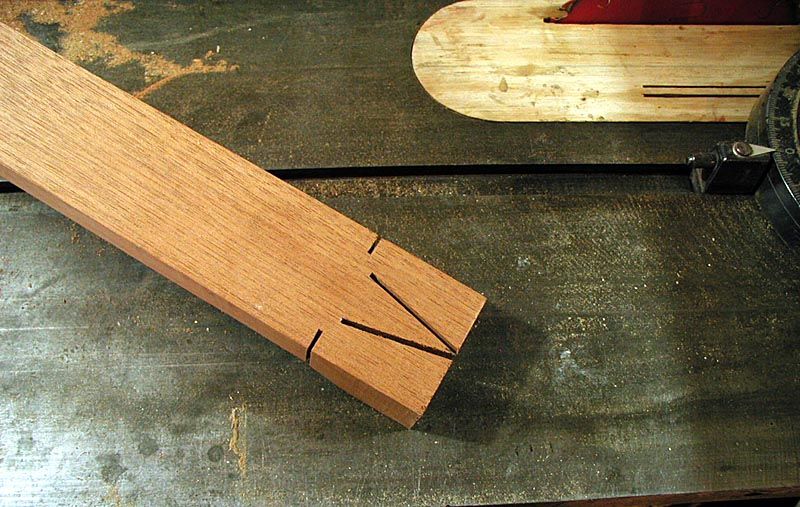

Then I measured for the neck shaft length and made some side cuts to demark off the dovetail section and the "V" stub that the peghead will fit onto.

These will be cut to full depth by hand later in the process.

Since I am only making one neck, I did not go to the trouble of making any fancy jigs. I just set the table saw blade to 12 1/2 degrees and screwed a piece of plywood onto the miter guage and "went at it". First I did a test cut on some scrap...just in case

Looks fine...the rest will be cut by hand

So here is the setup

I set the rip fence to get the cut at the correct distance from the edge of the blank. Then I clamp the neck blank perfectly vertical and make the cut..

...Then turn the blank with the other edge to the rip fence and make the second cut

Like I said, the rest of the cut will be finished by hand and everything cleaned up

I cut the peghead out of another piece of mahogany "scrap". It is 5/8" thick and about 3" wide (for now), and 7" long. The end that will fit to the neck shaft is squared off at a 15 degree angle, the angle of the peghead to the neck. I left the table saw set up the same. Used an offcut from cutting the peghead from a 1-piece neck as a spacer..it already is cut to the 15 degree angle. To make the first cut of the "V" I used the spacer block to angle the peghead blank 15 degrees back

Then I flipped the spacer block to tilt the peghead 15 degrees forward and made the second cut

Actually, I had made the cuts before these 2 photos, and I had just shifted the rip fence over a tad to recut and widen the "V". Then all I had to do is cut out the very tip of the "V" with a knife and clean it up with a knife edge file

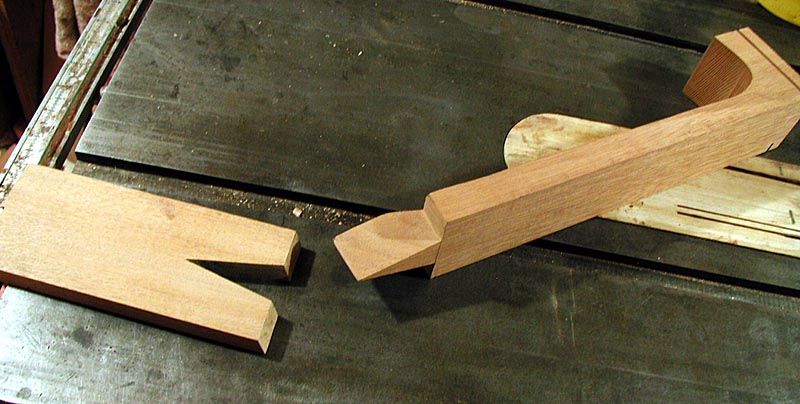

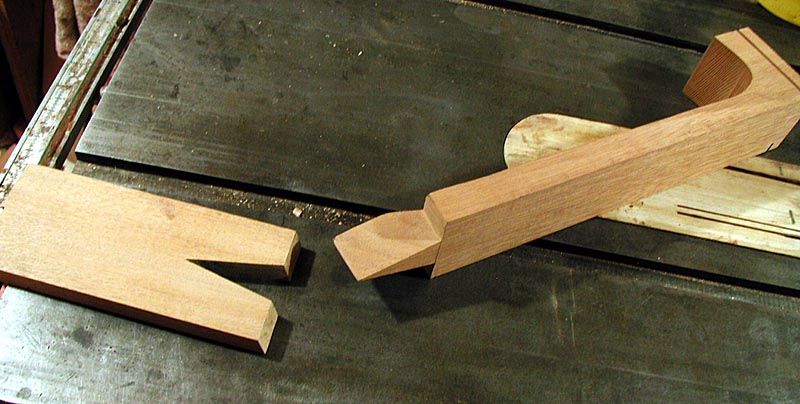

So here are the parts all cut

Only needed a slight bit of trimming (mostly used a small sanding block) to get a perfect fit

Here it is dry fit

I used thickened marine epoxy tinted brown to glue it up

So there it is. Just let the epoxy cure and clean it up. Now to be honest, I was kinda dreading the prospect of making this joint cuz I thought it would be one of those finikey things. But truth is that it went real easy and seemed to come out perfect. I might even do this on a regular basis

But I do owe a big thanks to Waddy and Arnt for showing the process and making it easy to understand. Without that, I might not have gotten up the nerve

G