Page 5 of 11

Re: Olivia's Pink Paduak

Posted: Tue Nov 04, 2008 6:45 am

by Eben

Most very way cool!

E

Re: Olivia's Pink Paduak

Posted: Tue Nov 04, 2008 6:55 pm

by Lefty

Raymond,

That label is a great finishing touch.

Lefty

Re: Olivia's Pink Paduak

Posted: Sun Dec 14, 2008 2:56 pm

by Raymond

Family obligations have kept me away from here, but not totally out of the garage. Did some rearranging and cleaning up, put wheels on the shop table, bought shelving for the wood, etc. Also made a couple of jigs...

One for cutting the purfling and binding prior to routing them

One for putting a bur on the scraper...

Based off the design that Stew Mac offers

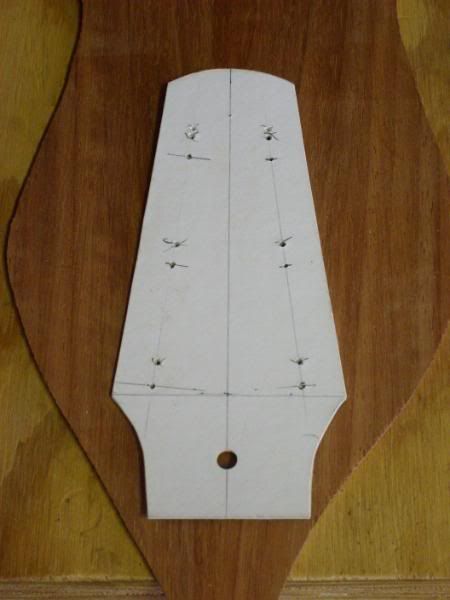

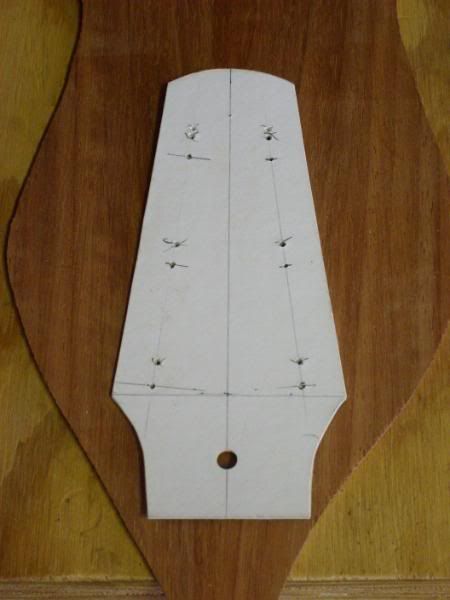

And lastly... because I get tired of trying to imagine how best to cut out the peghead

I made one out of acrylic, including a paper logo, and etched centerline and tuner outlines.

I also scraped the sides in preparation for binding.

Raymond

Re: Olivia's Pink Paduak

Posted: Wed Dec 17, 2008 11:31 am

by Eben

Nice work Ray!

I don't recall what you're cutting ledges with, but if you want to borrow my Metcalf rig, you're more than welcome!

Also love the headstock shape man! I've been thinking about simplifying mine, and you did a great job.

E

Re: Olivia's Pink Paduak

Posted: Wed Dec 17, 2008 10:10 pm

by Raymond

Thanks Eben. I'm using the variable speed dremel with the stew mac guide and a carbide bit.

There were certain areas where I was prone to chipping, so I decided to score the areas first and see how it goes.

Raymond

Re: Olivia's Pink Paduak

Posted: Thu Dec 18, 2008 10:39 am

by Eben

ohmyGod...

In that case,

I respectfully REPEAT my offer!

E

Re: Olivia's Pink Paduak

Posted: Thu Dec 18, 2008 1:16 pm

by whitespruce

Eben wrote:ohmyGod...

In that case,

I respectfully REPEAT my offer!

E

Hey E, if that scares you, you should se how Glen (GMG) and I do it

G

Re: Olivia's Pink Paduak

Posted: Tue Jan 27, 2009 11:58 pm

by Raymond

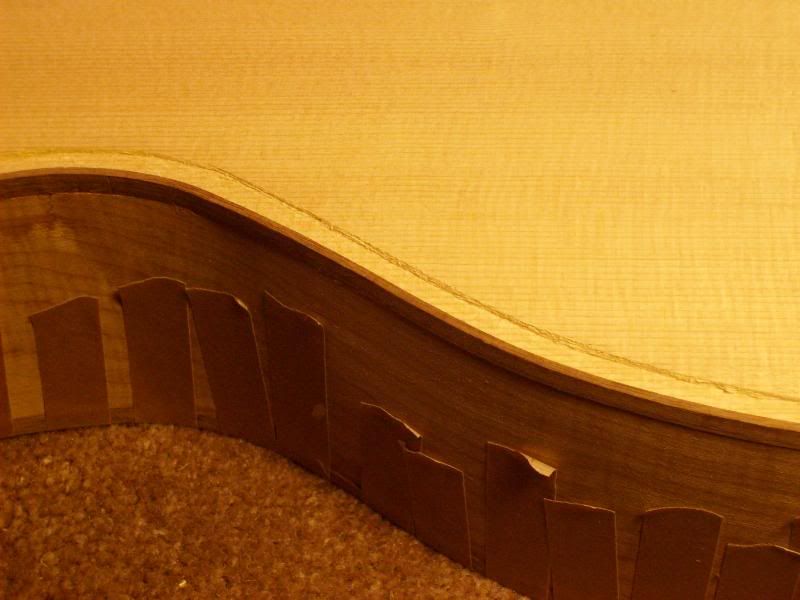

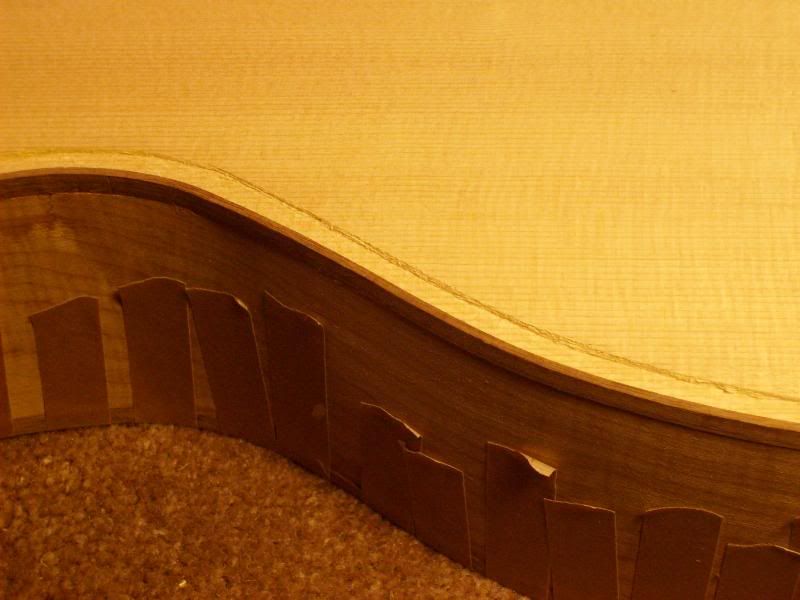

Well... when time in the shop gets a little harder to come by I guess I tend to stop taking pictures or posting. I went from just getting ready to cut the ledges for the binding to done with the binding and abalone purfling in pretty much one easy step...

The purfling cutter worked well and I cut the purfling ledge first and then the binding ledge using the Stew Mac Dremel attachment, and then glued the binding in place leaving a trough for the abalone purfling. I had no chipout on the top, back or sides so I think the purfling cutter did it's job.

I didn't take a picture of the trough, so here is a picture of the maple cutaway to show what I mean...

Did get a new electric bending iron for the binding and it worked great...

I think the curling iron was $5 at my local grocery store. Make sure to get one with a high heat setting. I'm thinking I'll buy a couple more and see if I can house the heater in a bigger iron shape...

I got the purfling from some supplier on Ebay... it's almost as thick as the top and was very reasonably priced.

I measured it for a tight fit, so I pretty much had to hand fit the pieces wedged in between 2 strips of .020 black fibre. I found the best tool for fitting was a metal fingernail file. Once I got the abalone in all the way around I flooded it with CA, starting with a light coating of thin CA followed by a heavier coat of thick CA.

After it was dried, I had to scrape and sand it smooth. Came out better than I thought it would first time out of the box.

Raymond