Well, since this thing is on a roll, I chugged along a bit more today. Read up a bit about installing bar frets. Main thing seems to be a whale of a lot of filing after they are in.

So I picked me out a fingerboard, used one that was a tad short for a regular size guitar, and ran it through the thickness sander. Took a strip of acrylic and laid it on the fretboard of the original guitar and marked the fret positions carefully. Then I took a little knife edge file and made notches at the marks so I had a fretting template.

Now the slots for these bar frets are way wider than regular "T" frets. That's because they are simply "bars" of nickel-silver. So the slots need to be the full width of the bars (about .055"). Well, I tried one of those thin kerf Diablo blades, but it cut too wide, about .063 or so. So I took a green 10" diameter silicon carbide grinding stone and laid it flat on the bench. Then I wet it and laid an old Diablo blade on it and started rubbing it around by hand. Worked one side for a while, then the other. What I was doing was grinding down the sides of the carbide tooth inserts. Took about a half hour and I had the blade down to cutting the correct size slots. In the process, it resharpened the corners of the teeth, so it cut like new

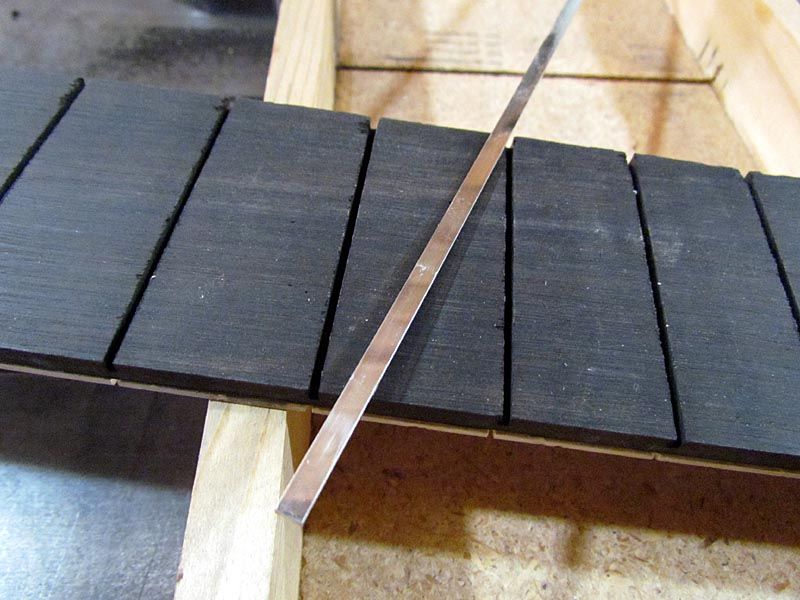

So I put the blade on the table saw and set up the sled I use for making kerfed lining. Then I used a couple of dabs of double stick tape to attach the acrylic template to the fingerboard blank. So here is what that setup looked like

Now, in this next photo you can see the little aluminum fin (red arrow) that I glued into a slot in the sled, and how it fits into the little notches in the fretting template

Just like downtown

So it just took a couple of minutes to slot the board

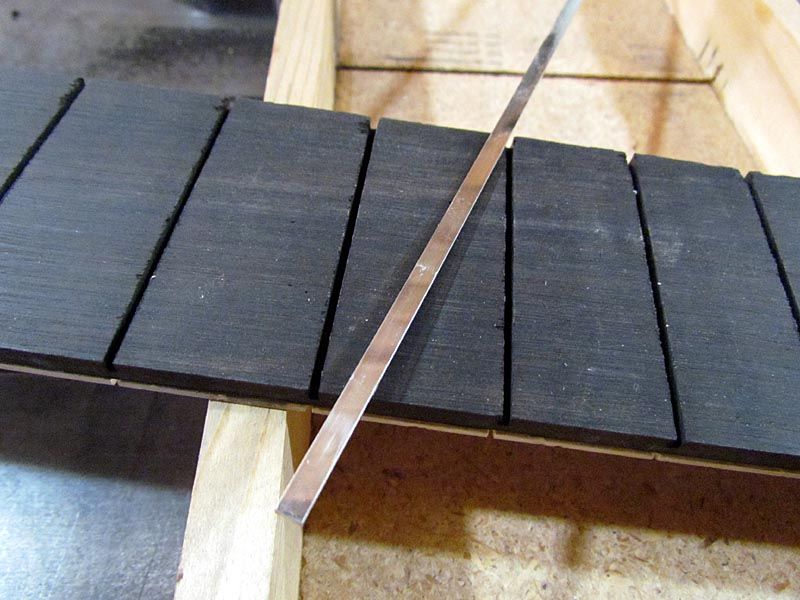

Ya, I know those slots look wide,

But here is the bar fretwire for comparison

So then I cut the board to length and tapered the sides, leaving room for the ivoroid binding. Here it is ready to be glued to the neck

I am using a scrap bone piece to get the nut slot the right width, and I drilled small holes at the 1st and 11th fret slot so I can pin the fingerboard in place while I glue it

So here it is glued and clamped

And ready for the binding

So that is all for today

One thing that I have been meaning to mention. Hopefully you have noticed that I make up "quick and dirty" jigs and such as I need them...nothing fancy and little time or $$ into them. The dovetail neck stuff and the tuner peg hole drilling guide are some good examples. Now, I suppose I could have spent a few hundred $$ and bought real stuff, or I could have spent more time and made up something a bunch more fancy. But what I am trying to demonstrate is that you don't have to. There are a lot of first time or low budget builders on this Forum and I want to show them that it CAN be done for little expense and one can "make do" quite well with quick home made stuff. I hope this is helpful to some of you. Down the road a bit, I will probably do a thread on more detail on some of these things and explain the how's and why's.......at least as they relate to that sorta different drum that I sometimes march to

Oh, and you have probably also noticed that I don't clean my shop or workbench very often

Thanks for looking,

G