Today's installment, as promised.

Fret Slots

Obviously, these are way different than the slots needed for regular fretwire. First, they need to be wider to accommodate the thickness of the bar stock. They also need to be flat bottomed since the bar frets seat directly on the bottom of the slot rather than following the profile of the fingerboard surface as in modern fretwire. So, I cut the slots on a table saw with a sled and a home made template. But first I need a blade that will cut the proper slot width. I want a snug, but not a forced fit, and I like the slot to start a bit tighter to allow me to hone a few thousands off the faces of the frets to get just the right fit.

I had honed down the sides of the teeth on a 7 1/2 Diablo thin kerf blade (which off the shelf cuts a sloppy 1/16" slot) to get a good fit for the LMI bar fret stock, which is .056" thick. These frets are a bit thicker, so I need to prepare another blade.

So, I start with a slightly used blade and rub both sides on a flat silicon carbide grinding wheel

This polishes the sides of the carbide tips and also trues up the irregularities in this (cheap) blade. I do both sides until I am satisfied with the thickness of the teeth. In this case, I aimed for about .o58"

Then I mount the blade with 5" diameter blade stabilizers

And make a test cut to check the fret fit.

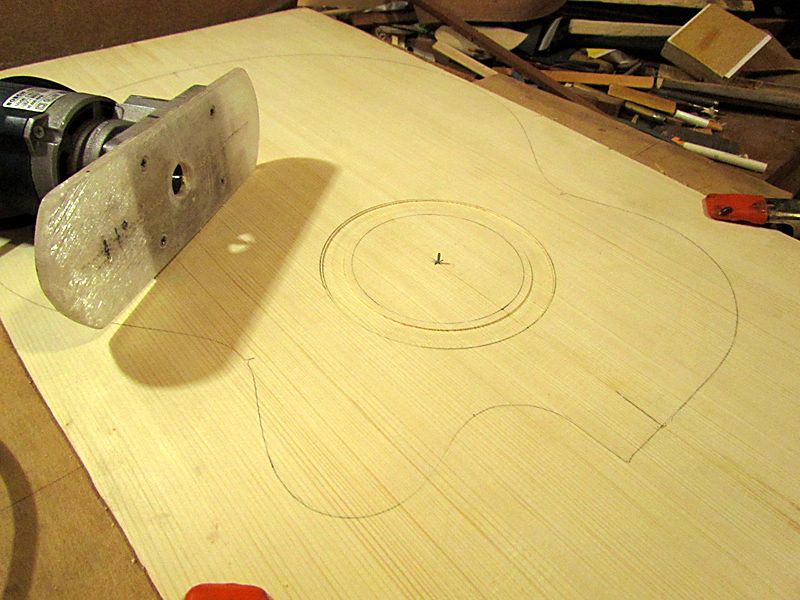

I do test cuts using my sled to get the slot depth set. Then I attach my slotted template (shop made) to the blank with double faced tape. The slots in the template register with a metal fin in my sled (red arrow) and I cut the slots

another view

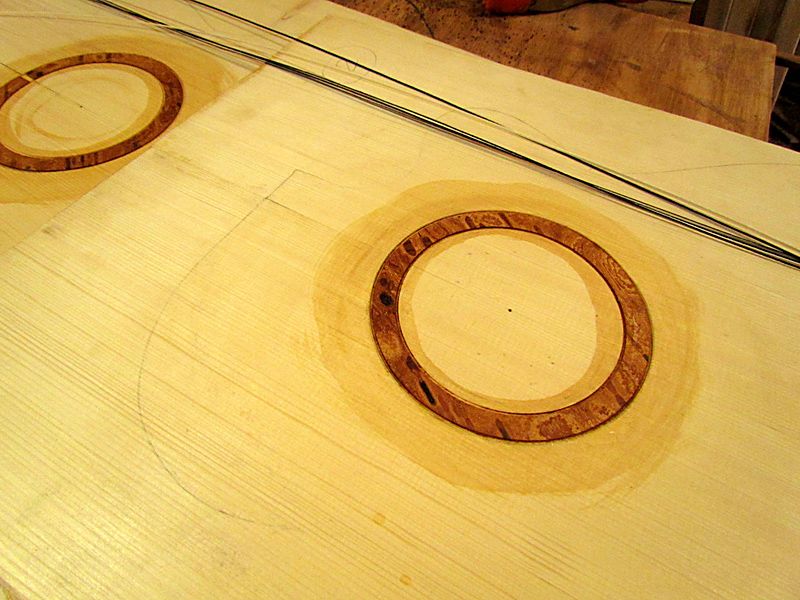

And here is the result

And here is a shot of the neck blanks and blocks

One about ready to go and the other needing peghead ears and the mortise and tenon cut.

Thanks for looking, comments and questions appreciated.

G